Thermal breaks and heat loss

Determining the thermal conductivity of a material means we can find out the rate at which heat flows it. This helps us work out the efficiency of the material before it is incorporated within a building envelope. Two factors on which heat flow is dependent on, are the area of a wall or roof assembly for instance and temperature difference from inside to outside. If a material is specified that features higher thermal conductivity it will allow a transfer of heat or energy at a higher rate in the same conditions of temperature.

You can distinguish a thermal break by its thermal conductivity, this is often referred to as the K value, and the thermal resistance, which is often referred to as the R value. You can calculate one of these values by using the other which helps to determine the overall efficiency of the thermal break material in question. Determining these values helps create thermal models which detailed the efficiency of the building envelope and roof assemblies, it’s important for architects and specifiers to understand these values so efficient structures can be created and built. This allows designers to make meaningful changes before construction begins.

Thermal modelling is an important step in the process of creating and adjusting details in efficient structures. When a conductive material is specified within a structure such as steel the heat does not travel in parallel paths. If it did travel in straight lines, a simple maths equation and area weighted averaging could be used to determine the heat flow. Also interfaces and transitions are complex and may contain corners or additional features to make the calculation more difficult.

How can thermal breaks help?

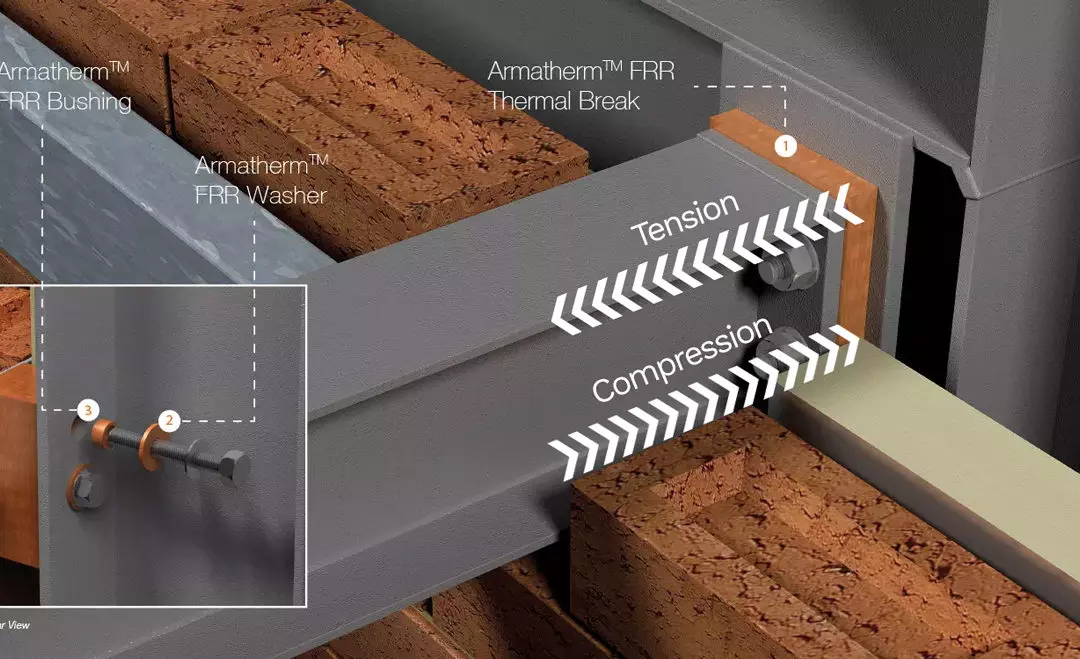

When looking at balcony installations, as much as 30% of a wall assemblies heat loss can be lost here. A steel z-girt can reduce the R value of a wall by up to 50%. Thermal bridges also occur within roof penetrations, canopies, masonry shelf angles, column bases and foundation wall connections.

When creating a thermal model you will be able to see the actual R&U values of the assembly. Once a thermal break is incorporated you will be able to see how much the heat loss is improved with the addition of the material. It can also help reveal where condensation is likely to occur by revealing the surface temperatures of the materials within the assembly.

The closed cell polymer properties of a thermal break means to be effective, it must have less thermal conductivity than the materials it is being used to break. In certain scenarios using a thermal break that is too thin will decrease the overall effectiveness of the thermal break due to the area of highly conductive steel being increased. Extensive research has shown that the thickness to achieve significant heat loss reductions should be at least one inch.

At any connection where a thermal break is specified, the main aim is to find the appropriate thickness and area combination to help the roof assembly or wall meet EU value requirements. With new energy codes and regulations, this is more important than ever.

Condensation

A thermal break helps work towards keeping the interior surface of connections above the dew point. Buildings that experience higher than normal levels of humidity, due to geographic location or usage, are more likely to experience issues with condensation and so effective thermal breaks should be considered by specifiers

Thermal breaks help control material surface temperatures. Thermal bridges allow heat from interior conditioned spaces to flow through the envelope and into the outside world. To prevent the occurrence of condensation, the surface temperature of any material used within the structure, must be kept above the dew point to stop condensation occurring on these interior spots.

Armatherm™ offers a wide range of thermal break solutions to counteract and minimize thermal bridging as much as possible. Some of our thermal break materials include Armatherm™ 500, Armatherm™ FRR and the Armatherm™ Z girt. Thermal breaks have proven their effectiveness at working towards more efficient structures which meet new and upcoming regulations, and their advantages should not be overlooked. To find out more you can get in touch with our team of experts who will help specify the most effective thermal breaks for your project.