Why Is Compressive Strength Often Overemphasised in Construction?

The stronger the better – a phrase that makes sense when it comes to construction and building projects. Every element should be the strongest it can be to withstand the weight and pressures of the rest of the build, but should this always be the case? The team at Armatherm is often approached by architects and specifiers looking for thermal breaks in the highest compressive strength available, no matter what the application is.

What’s the Relationship Between Compressive Strength and Thermal Performance?

To put it in simple terms, this is the wrong approach. Thermal breaks prevent thermal bridging and reduce heat loss, depending on the products, the qualities differ. A general rule of thumb is the lower the compressive strength, the higher the thermal isolation effectiveness. With energy standards ever increasing in a bid to achieve net zero energy standards, it’s more important than ever that the industry does not overcompensate with compressive strength for the application.

Where Are Structural Thermal Breaks Commonly Used?

Structural thermal breaks are a key player in the construction of energy efficient buildings that need to meet strict energy codes. The different locations where thermal breaks are incorporated can range from column bases and balcony connections right through to cladding and masonry shelf angles, with each requiring very different properties in terms of load bearing capacity.

For example, internal steel columns will traditionally extend through the building envelope floor slab and insulation at their base. In low temperature buildings, such as cold storage units, this creates a bridge for energy to transfer through. This is also present within support floors or roof overhangs.

Why Does Application-Specific Strength Matter?

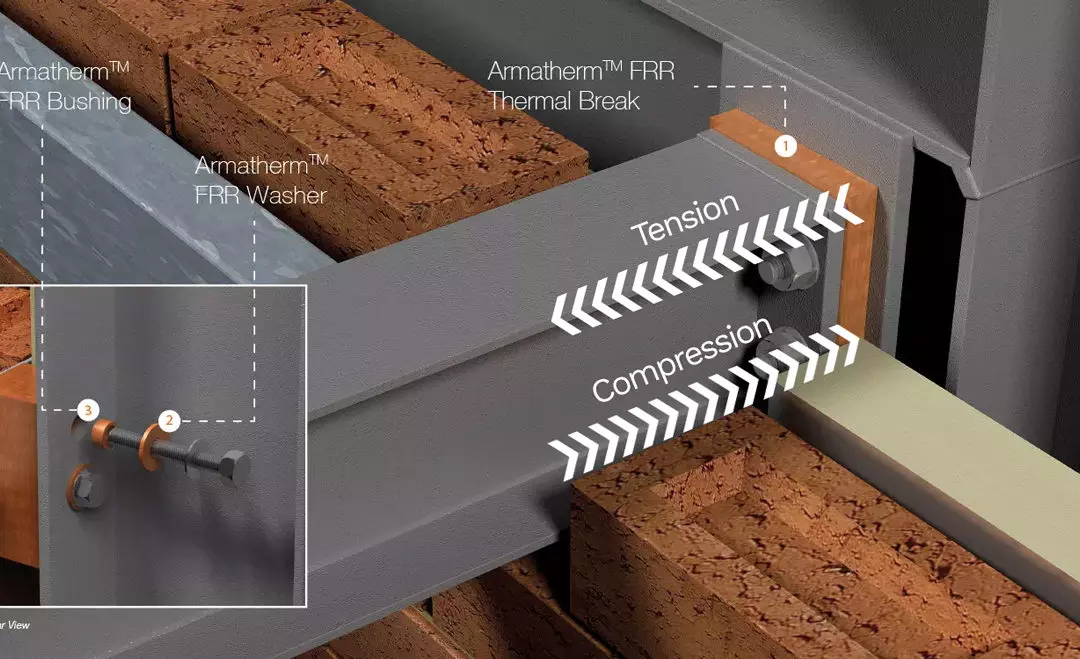

A structural thermal break’s primary objective is to reduce the cold bridge within the building envelope, but they must also maintain the structural integrity of the connection. In a balcony situation for example, the steel to steel location would require a thermal break such as the Armatherm FRR range.

The compressive strength can be calculated by advising the load the thermal break will be exposed to, along the length x width of the thermal break which would then be mirrored to the size of the end plate, faceplate or column base details (connection design).

What Happens When High Strength Materials Are Used Incorrectly?

It’s common for structural thermal breaks suppliers to cater for high compressive strength only, due to a limited range of material. This again results in materials with a high compressive strength being used in applications that do not require it. Unfortunately this means the applications could potentially be made more thermally efficient by using a thermal break with lower compressive strength.

Armatherm has developed a product range that caters for all requirements and applications. With solutions that have a compressive strength at the lower end, as well as the higher end of the spectrum. This means we can supply the right material for the specific application and project goals.

How Can Overcompensating on Strength Affect Budget?

Another factor that suffers with overcompensating on compressive strength, is budget. Materials with higher compressive strength are usually more expensive. So when these materials are used for applications which do not require it, the budget is wasted. At Armatherm, we are dedicated to ensuring you have the correct materials for the exact project you’re working on. This is why we have developed a diverse range of products over the years, meaning we are the only thermal breaks manufacturer globally to offer such a wide variety of products to the market.

Armatherm has a dedicated support team, detailed documentation and online learning resources, to help advise on the most appropriate material for your project. If you would like to learn more, get in touch with one of our consultants today.