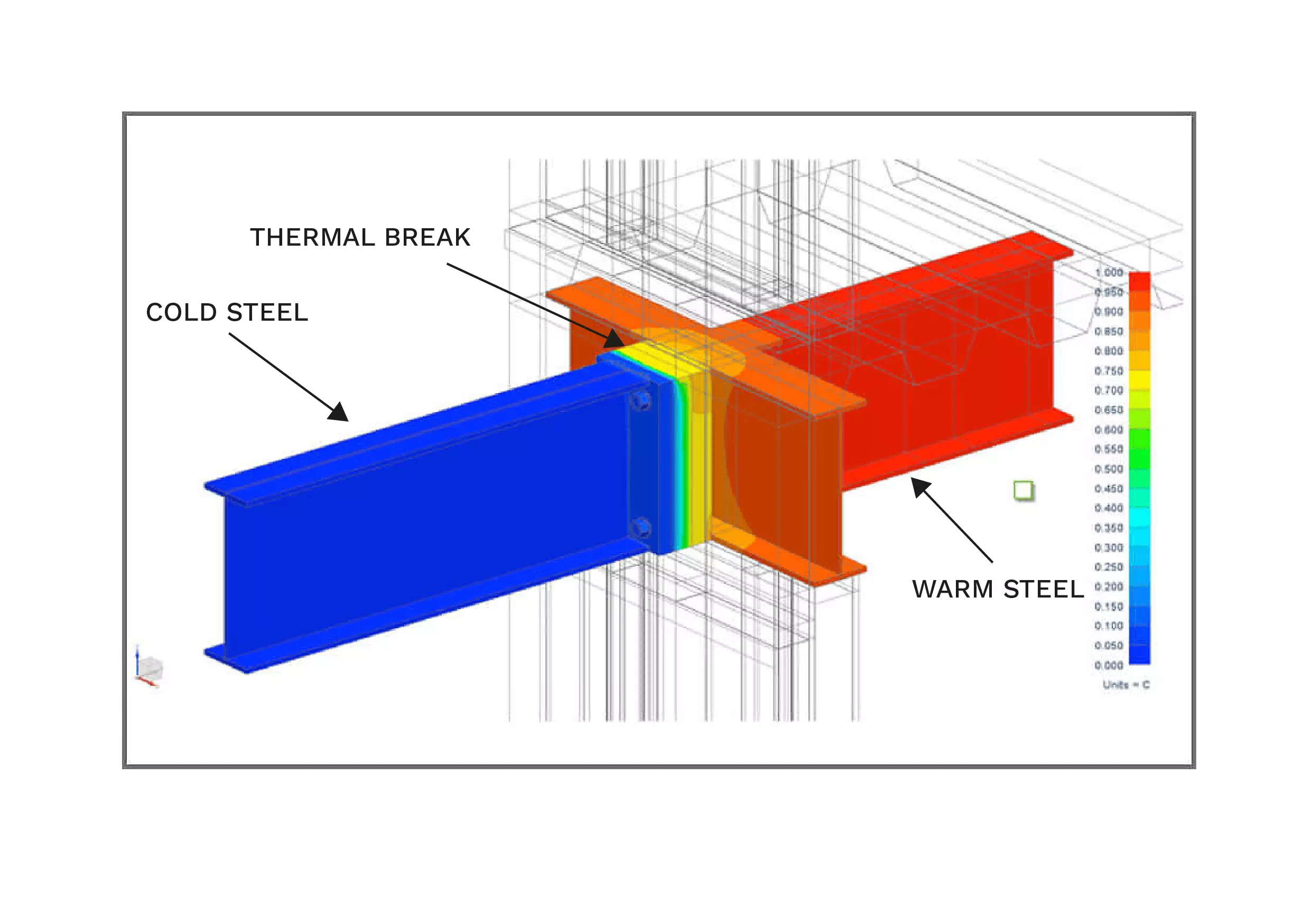

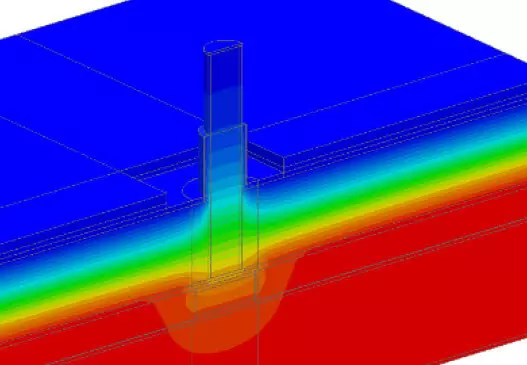

A thermal bridge, also knows as a heat bridge or a cold bridge, is the term used to describe areas within a building envelope where heat can flow through easily via conductive materials, bypassing any insulation materials. These occur when a component with high thermal conductivity disrupts the continuous insulation and creates a pathway for heat / energy transfer. These bridges provide a path of least resistance for heat transfer, resulting in heat loss or gain in these areas, alongside reduced energy efficiency and creating potential condensation issues.

When determining a building or structures overall energy efficiency, thermal bridging plays a vital part as even with some of the most efficient solutions on the market, these can be rendered almost redundant if significant thermal bridges are present. Let’s take a closer look at the effective strategies to mitigate the effects in order to reduce energy bills and the impact on the environment.

Examples of thermal bridging

There are several different factors that can contribute towards a thermal bridge occurring. Some of the most common causes include structural elements such as concrete slabs and steel beams that conduct heat past any insulation. Other examples include window frames, parapet, brick shelf angles, balconies and connections that link or connect different building components and materials.

Differences in thermal conductivity

Common building materials have different levels of conductivity, so some are much higher than others. This means they create a path of least resistance. When these materials connect to other elements, they can create a literal bridge across the insulation layer, they can facilitate the flow of heat either into or out of the building envelope. Examples include:

• Structural connections – concrete slabs, steel beams and metal studs

• Door and window frames made of metal which can create localised areas of heat transfer, compromising the effectiveness of any insulation

• Building component connections such as walls and roofs

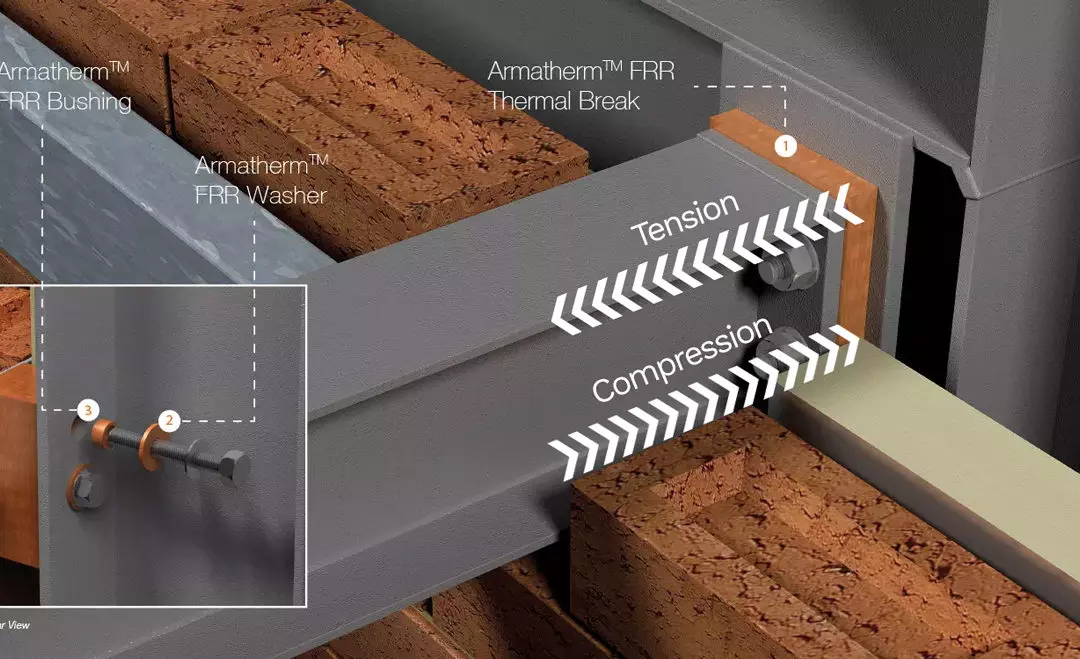

Fixings and fastening

Even the smallest elements that may seem minor in the grand scheme of a construction project can contribute towards creating a thermal bridge within the building envelope if they’re not correctly or properly insulated. Examples include:

• Fastenings and brackets, including any screws and nails which can create areas of localised heat transfer (these small elements can conduct heat more easily)

• Switches and electrical outlets which can allow heat to bypass the insulation, leading to the energy loss and potential cold spots

• Cantilevers and balconies which extend further beyond the building envelope can act as conduits for heat transfer